Phase One

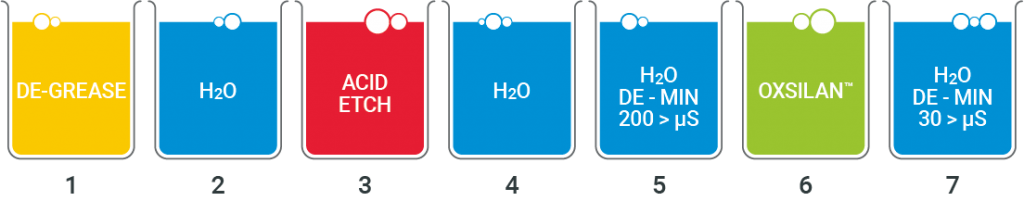

Pre-Treatment

This stage is vital in allowing the paint finish to perform to its full potential. All paints are porous and will over time allow atmospheric conditions to permeate through the coating onto the metal. To safeguard against this, all substrates are chemically pre-treated in order to protect against corrosion and promote good adhesion.